As part of my participation at the Rangemaster Shotgun Instructor Development Course I had to give a presentation on a topic assigned before class. My topic ended up being Foster and Brenneke slugs. This is essentially that presentation as a blog post.

How Did We Get Here

Before shotgun slugs evolved into what they are now, they were just round balls of lead. Essentially a musket ball since “shotguns” were basically that, a smooth cylinder bore gun without any constriction in the barrel. The basic round ball did well enough.

What changed? What made the round ball no longer an acceptable projectile? Shotgun chokes became more popular and common place on shotguns around the 1870’s. What happens when you squeeze a round object through a constriction? It will no longer be round. When we think about projectiles fired from a smoothbore firearm, being sort of oval shaped doesn’t do much for the accuracy department.

Initially, people tried just using a lead ball that was actually smaller than the size of the bore so that it could hopefully maintain its shape (at least mostly) as it squeezed through a choke. That didn’t help much though, and better solutions were required.

Today, we have three basic slug types, but only two that are really of interest the us. The third type that we don’t really care about are sabot slugs. These are slugs purpose built for rifled barrels. Rifled barrels generally suck at shooting shot loads, so they don’t get much play outside of specific hunting applications. We are mostly interested in shotguns used for personal defense, where buckshot loads are our preferred ammunition choice, which means we need smoothbore guns. For smoothbore shotguns, the two general types of slugs that we are most interested in are Brenneke and Foster slugs.

The Foster Slug

The Foster slug is what we in the United States are most likely to think of when we think “shotgun slug”. Brenneke slugs actually predate the Foster slug, but being a European invention, they are not as common as what is often termed the “American shotgun slug”.

Carl Foster came up with what we now call the Foster slug in 1931. In the midst of the Great Depression, he was trying to find a way to make the humble smoothbore shotgun a more capable hunting implement while on a budget. Carl Foster started off making these slugs out of pure lead in his garage, filing the grooves, or rifling, in the side of the slug by hand. The Foster slug was a way to extend the practical range of the shotgun, and make it more capable of taking down larger game animals. A worthwhile endeavor in a time when resources were meager and buying food sometimes difficult.

Foster slugs are characterized by being made of a softer lead, with a deep hollow cavity in the base. Around the outside of the slug there are typically 14 ribs, or “rifling”. The slug gets its stability from having a weight forward design though, not the rifling. The thicker and heavier front gives the slugs its stability at it wobbles itself downrange. Much like a sock full of wet sand, or a shuttlecock. The “rifling”, combined with the hollow base and softer material, helps the slug squeeze itself through any choke constriction at the end of the shotgun’s barrel, addressing our issue with just using round balls.

Foster finally upgraded his garage production to using a custom mold made by Lyman and was selling the slugs to his neighbors. He presented the slug design to Remington after a couple years of making them on his own. Remington, in all their wisdom, passed on the idea. Foster went to Winchester next, and the people running Winchester were apparently smarter than the people running Remington at the time. The Foster slug became available as a retail item from Winchester in 1936. Remington realized they missed the boat, and started selling their own version of the Foster slug a year later.

The Foster slug in its basic form is largely unchanged over the last 90 years. A basic Foster slug from today, still looks much like a Foster slug from then. The most notable advances with regard to the Foster slug are primarily changes in wad technology. Initially wad columns consisted of a hard cardboard disk just behind the slug, a soft fiber wad that acted much like a cushion, and then another hard cardboard disk to be a gas seal and propel the slug down the barrel of the shotgun.

Today, in basic options from Winchester and Remington the cardboard disks have been replaced by polymer disk, but the fiber wad is still there. In some other product options from Federal and Hornady the wad column has been combined into a single polymer unit, sticking all the parts together. The slugs themselves though all closely resemble each other, although performance will vary based on manufacturing processes and tolerances.

Federal’s TruBall Wad System

One of the more significant advancements in wad technology for the Foster slug has been Federal’s TruBall wad system. It uses a one piece polymer cushion wad and gas seal combined with a polymer ball placed in the hollow of the slug to consistently center the slug in the bore of the shotgun when it is fired. The more consistently the slug is centered, the more consistent the flight of the slug will be from shot to shot, giving us better accuracy. In my experience, the TruBall Foster slugs from Federal are significantly more accurate than standard Foster slug counterparts out of smoothbore barrels. I have heard reports from other shooters and instructors that this has been their experience too.

Federal’s Deep Penetrator Rifled Slug (DPRS)

The other notable development in the world of Foster slugs is Federal’s attempt to improve the penetration characteristics of the slug design. Foster slugs are pretty good at extending the range of the shotgun. What they generally are not considered to be that good at is defeating intermediate barriers, or other tough skinned targets like dangerous or large game animals. Since the lead alloys used in Foster slugs are so soft, they tend to over expand and in some cases fragment. This obviously doesn’t help the penetration.

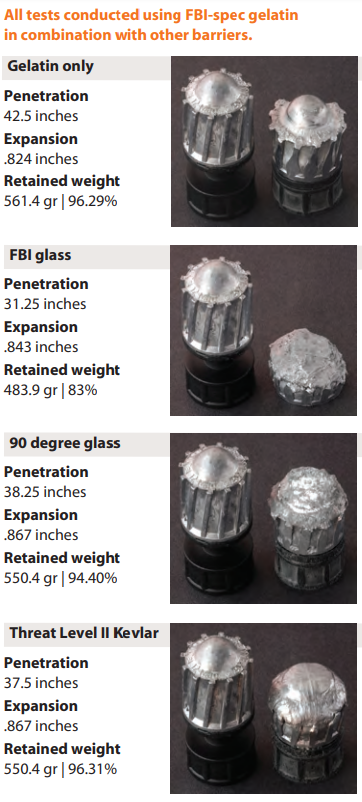

To try and solve this problem, Federal decided to come up with a way to harden a Foster slug. They used a slightly harder lead alloy for the slug itself, and then plated it in copper. They put a tough skin around the slug, so that now it doesn’t deform significantly when it impacts the target, increasing penetration. Essentially the same concept as using copper plated buckshot to maintain the roundness of the shot as it is launched down the barrel of a shotgun.

The Brenneke Slug

Back to the Brenneke. In 1898 Wilhem Brenneke created the initial version of what we all know now as a Brenneke slug. This first version looked a little different than what we consider to be the classical version of a Brenneke, but it was close. It had a cylindrical shape, a flat nose, and 6 ribs around the exterior of the slug. Attached to the back of the lead projectile with a screw was a felt wad. Since the slug itself was essentially a solid projectile, the attached wad is is what gave it a weight forward design and the stability that it needed to be useful for hunting out to 75-ish yards.

Brenneke was looking for something that could make the shotgun a more capable hunting implement, and wanted something that would provide sufficient penetration and cause significant enough tissue damage to have a high likelihood of giving the hunter as clean of a kill as possible. That should sound familiar, although Brenneke did it over 3 decades before Foster.

Brenneke had a heavy emphasis on a projectile that would penetrate well, and cause significant tissue damage. Because those were among his top priorities, he used a relatively hard lead alloy so that the slug would not deform much on impact, and the sharp shoulders of the slug cut tissue rather well. Basically a 3/4″ diameter wadcutter. At least that is how it started.

The 6 ribs around the exterior of the slug were to allow the slug to swage through chokes without compromising the integrity of the slug itself. Remember, this is how we got here to start with, needing to shoot slugs through choked barrels. Brennekes are claimed to be safe for any of the normal choke constrictions, even a full choke. The ribs are likely deep enough that this is true. I haven’t tried it personally, and safe for a handful of shots is probably different from safe for a couple cases worth.

Over time, the pointed nose in the center of the front of the slug was added, and the number of ribs was doubled to 12. Everything else stayed the same for a very long time. The fiber wad wasn’t replaced as the primary wad system until the early 2000’s. Brenneke finally made the move to modern plastics with a two piece wad system that is now what they use on most of their slug loads. Although, the classic slug is still available if someone wants to roll old school.

With the current polymer wad, instead of using a screw to attach the wad to the back of the slug, it sits inside a hollow portion of the slug and is retained by several detents. When the slug is fired, the stem and back portion of the wad collapse into the front, and it creates a sort of plastic skirt that stays attached to the slug as it travels downrange. Or at least it is supposed to. On occasion the wad will become detached, and accuracy usually degrades when it does since the wad is how the projectile derives much of its stability.

Where the Shotgun Slug Fits

Shotgun slugs do two things for us. They extend the practical range of the gun, and they allow us to shoot through things, or into things. Probably most notably vehicles, but can also work against barriers in general.

Brenneke slugs are known for doing both of those things, but mostly for being exceptional at defeating barriers. Due to their harder lead alloys, pretty much every version of the Brenneke will defeat barriers better than the typical Foster slug. Some specific versions of the Brenneke are designed to increase that capability even further.

Foster slugs have their limitations with regard to penetration, except for the one exception, Federal’s Deep Penetrator Rifled Slug. The nice thing about Foster slugs is that they are readily available everywhere in the United States. There is not a major manufacturer that isn’t pumping out their own version of this type of slug. They are plentiful, and usually pretty cheap.

Where the Foster slug might have the edge on the Brenneke is reliable accuracy. In my experience, a well selected Foster slug can deliver exceptional accuracy, even out of smoothbore shotguns. Since Brenneke slugs can have issues with wads becoming detached and accuracy suffers as a result, I would give the Foster slug the edge. Other people’s experience may vary though.

Which one you might want to use will depend on what criteria you need your shotgun slug to meet, or perhaps what is most readily available. The mission drives the gear train, as they say. At least most of the time.

Nice report young man. A lot of good information here.

LikeLiked by 2 people

Great history aboutbBrenneke & Foster slug 🙂

Imlookmfwd. To reading what you have to say about Ddupleks Mon-Lit slugs..

LikeLike